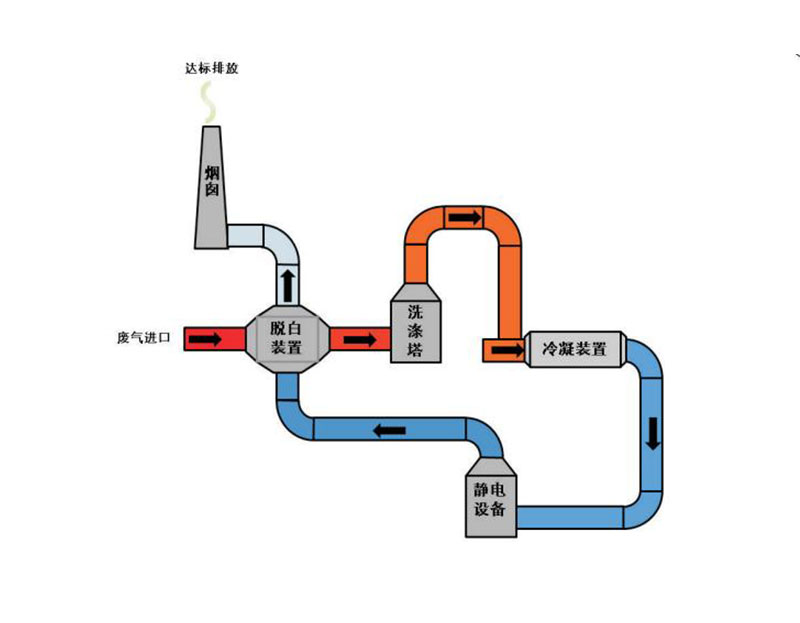

In the process of waste gas treatment of domestic setting machines, spray washing will be done first. After washing, the water content of waste gas increases significantly, and a large number of white smoke plumes are formed after discharge. Therefore, whitening transformation is needed to improve visual pollution.

Operating principle:

We carry out whitening transformation through "condensation + reheat" method, in which the heat of the end flue gas heating comes from the front end, because the waste gas of the setting machine contains oily substances and wool is easy to block the equipment. In view of this phenomenon, our company specially designed a setting machine waste gas heat recovery product, effectively solve the problem of easy clogging and difficult to deal with equipment.

System advantages

1.White fog can be eliminated by using the waste heat of high temperature exhaust gas without additional energy consumption

2.This bleaching device is patented by the company, which has the characteristics of low ventilation resistance and not easy scaling of oil and wool

3.Automatic cleaning, covering 100% area, no backwater area

4.The equipment uses corrosion-resistant materials with special surface treatment

5."Whitening + exhaust gas purification" one-stop design, purification efficiency of more than 95%

Bleaching of flue gas of mixer in asphalt plant

Boiler flue gas bleaching

Bleaching of molding machine flue gas

Coking flue gas bleaching

Primary air preheating of boiler

Flue gas waste heat heating demineralized water

Heating oven exhaust air

Dyeing wastewater heating dyeing tank water

Phase change condenser

Natural gas heater

SGH steam heater

High viscosity gas-liquid heater

Drive type air cooler

High efficiency air preheater

High efficiency waste heat recovery device