Most of the boiler outlet exhaust temperature is more than 100℃, the temperature of the flue gas directly discharged into the atmosphere, higher exhaust temperature causes heat loss. The heat of flue gas at the end of boiler is recycled through superconducting heat exchanger, and then the brine is heated to reduce the heat loss of boiler. Through the structure design of superconducting heat exchanger, the exhaust temperature can be achieved at least 40℃.

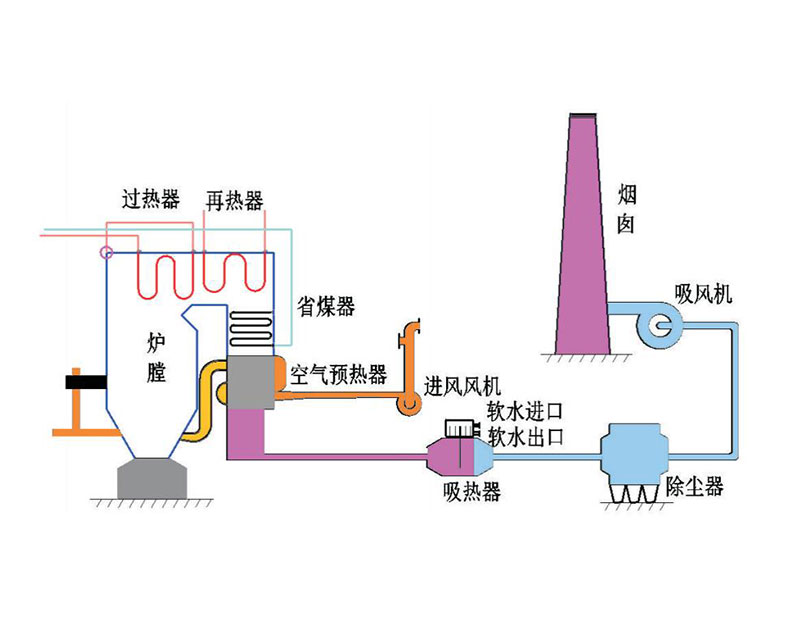

Schematic diagram of waste heat recovery and utilization process

The waste heat of flue gas from boiler outlet is used to heat the boiler with superconducting material.

1. This technology uses superconducting energy saver to heat soft water from flue gas at boiler outlet, which can save steam consumption.

2. Compared with heat pipe, superconducting medium will not produce non-condensable gas for a long time operation, and can inhibit metal oxidation, and has a long service life.

3. Due to the isotherm of superconducting medium, the heat absorption surface can be adjusted to avoid acid dew point corrosion of flue gas.

4. Each superconducting pipe runs independently, and the damage of a single pipe will not affect the operation of the system and is convenient for maintenance; Once a single heat transfer tube is damaged, the system must be stopped for maintenance.

5. The decrease of flue gas temperature in the feed system is beneficial not only to desulfurization reaction, but also to the operation of dust collector.

Bleaching of flue gas of mixer in asphalt plant

Boiler flue gas bleaching

Bleaching of molding machine flue gas

Coking flue gas bleaching

Primary air preheating of boiler

Flue gas waste heat heating demineralized water

Heating oven exhaust air

Dyeing wastewater heating dyeing tank water

Phase change condenser

Natural gas heater

SGH steam heater

High viscosity gas-liquid heater

Drive type air cooler

High efficiency air preheater

High efficiency waste heat recovery device