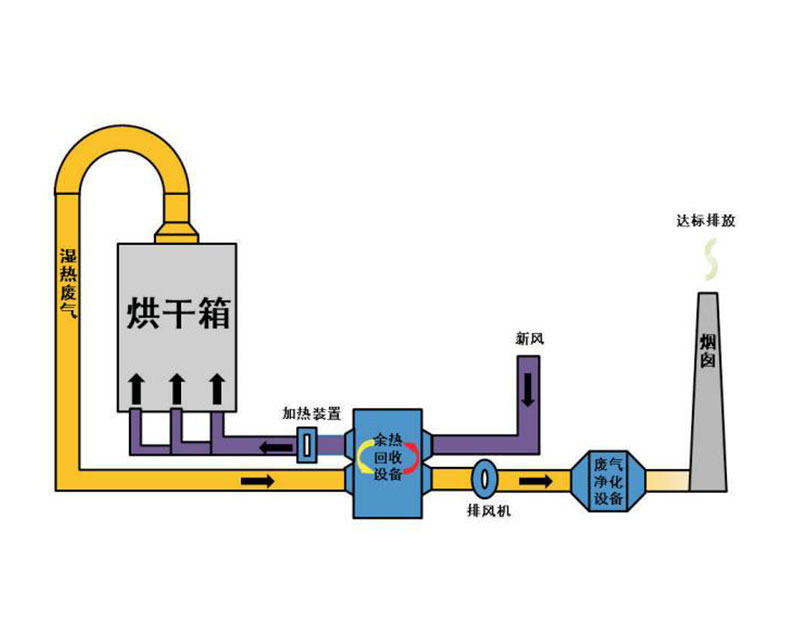

Drying box in the baking material, the need to constantly add fresh air to discharge the moisture and odor of the material to achieve the drying of the material. The supplementary fresh air is basically normal temperature air, consistent with the environmental working condition. The waste heat recovery device can heat the normal temperature air to a certain temperature to reduce the energy consumption of the heating device.

Operating principle diagram

1. The technology uses the waste heat of hot and humid air in the oven to heat the cold air and reduce the consumption of natural gas in the heating device.

2. Compared with heat pipe, superconducting medium will not produce non-condensable gas for a long time operation, and can inhibit metal oxidation, and has a long service life.

3. Each superconducting pipe operates independently, and a single failure will not affect the operation of the system.

4. Design removable structure, can be single disassembly cleaning, long service life.

5. The system will not cross wind, hot waste gas will not enter the oven, to ensure the drying quality.

6.Can be "heat recovery + exhaust gas purification" one-stop design, energy saving efficiency of more than 50%, purification efficiency of more than 95%.

Bleaching of flue gas of mixer in asphalt plant

Boiler flue gas bleaching

Bleaching of molding machine flue gas

Coking flue gas bleaching

Primary air preheating of boiler

Flue gas waste heat heating demineralized water

Heating oven exhaust air

Dyeing wastewater heating dyeing tank water

Phase change condenser

Natural gas heater

SGH steam heater

High viscosity gas-liquid heater

Drive type air cooler

High efficiency air preheater

High efficiency waste heat recovery device