Domestic asphalt mixing station specializing in the production of asphalt mixture. Asphalt mixture is a mixture of asphalt and dried stone, which produces a lot of wet flue gas during drying. Much of the water vapor in the wet flue gas comes from water in the stone and from the burning of natural gas. After the wet flue gas through the bag filter, the temperature is basically 80℃~100℃, the humidity is 60%~80%. When entering a lower temperature environment, the temperature of flue gas drops sharply. Under the condition of constant moisture content, water vapor in the flue gas presents a supersaturated state, and condenses into water droplets rapidly with dust and other particles as condensation nuclei. These droplets scatter under the light, resulting in white plume.

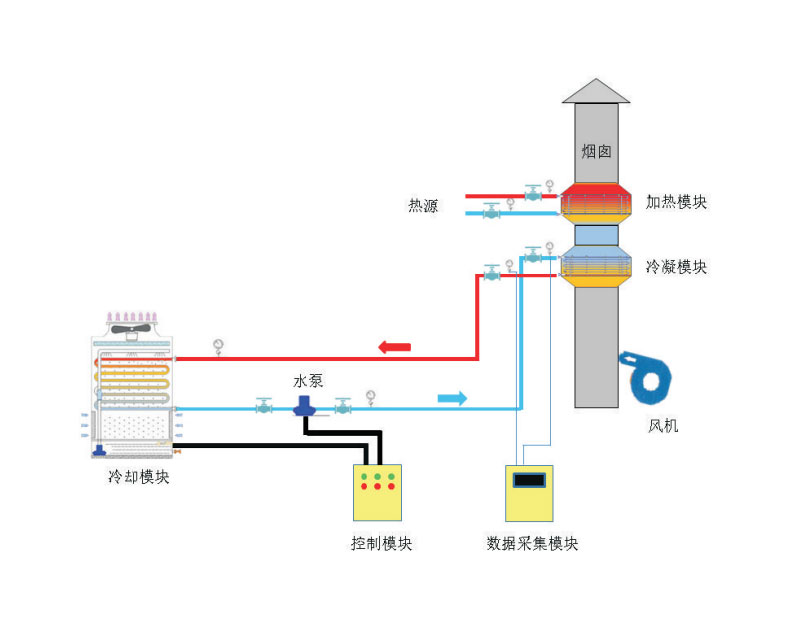

Process flow chart of bleaching system

The mixer whitening system includes condensing module, heating module, cooling module, control module and data acquisition module.

● The function of the condensation module is to cool the flue gas to a certain temperature and remove some pollutants in the flue gas;

● The heating module function is to eliminate white smoke plume;

● The function of the cooling module is to discharge the heat absorbed in the system through the cooling tower. Since this heat is indirect heat dissipation, it has no impact on the environment;

● The function of the cooling module is to discharge the heat absorbed in the system through the cooling tower. Since this heat is indirect heat dissipation, it has no impact on the environment;

● The function of data acquisition module is to collect all the data in the condensing system and heating system, and monitor the continuous and stable operation of the system.

● Full automatic control, without artificial operation, to run the system.

● The system is fully closed and independent operation, safe and stable use.

● Modular setting, a large system divided into different subsystems, simple and convenient maintenance.

● System design compact structure, small footprint

● Further reduce the content of pollutants in flue gas, improve the emission standards

● The system uses small power, low operation cost

● Energy-saving design, through superconducting technology heat transfer from front to end heating, reduce energy consumption.

Bleaching of flue gas of mixer in asphalt plant

Boiler flue gas bleaching

Bleaching of molding machine flue gas

Coking flue gas bleaching

Primary air preheating of boiler

Flue gas waste heat heating demineralized water

Heating oven exhaust air

Dyeing wastewater heating dyeing tank water

Phase change condenser

Natural gas heater

SGH steam heater

High viscosity gas-liquid heater

Drive type air cooler

High efficiency air preheater

High efficiency waste heat recovery device